P20 Steel High Hard

High Hardness Steel P20 – HRC 40

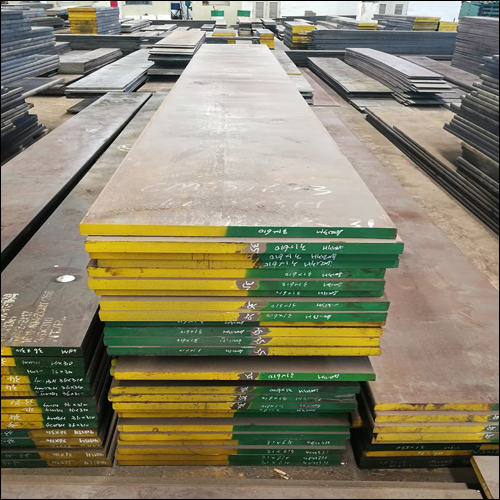

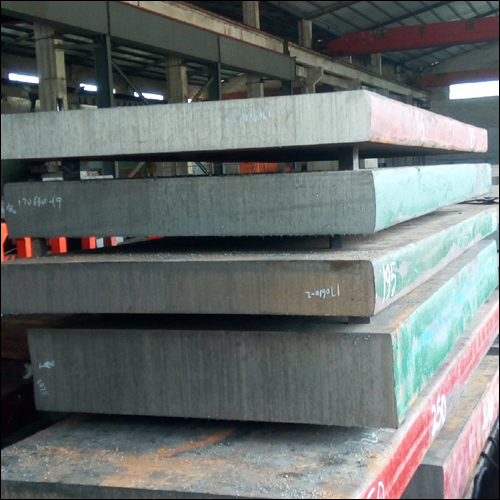

We are Supplying High Hardness Steel P20 – HRC 40 for Plastic Moulds. We have High Hardness Steel HRC 40 – Plastic Mould Steel, P20 Grade 1.2738, P20 Steel 1.2311 and 1.2316 in ready stock.

We Supplying High Hardness Steel P20, HRC 40 for Plastic Moulds making. We have in stock High Hardness Steel P20 Steel Plates in all sizes. HRC 40 Plastic Mould Steel best for production tools making.

Preheating : As P20 is sold in a pre-hardened position, hardening heat treatment is not needed. After machining and intermittently during pottery, the steel must be thermally stress relieved by heating to 900ºF (482ºC), equalizing and holding for one hour per inch (25.4mm) of width, and cooling in air to ambient heat.

In those rare circumstances where the steel must be re-hardened, the steel must first be annealed prior to solidification.

Austenitizing (High Heat) : Heat rapidly from the preheat to 1550ºF (843°C). Soak for 30 minutes for first inch (25.4mm) of breadth, plus 15 minutes for each additional inch (25.4mm).

Quenching : Pressurized gas, or interrupted oil to 150-125ºF

(66-51ºC).

For oil, quench until black, at about 900°F (482°C), then cool in

still air to 150-125°F (66-51°C).

Tempering : Temper immediately after quenching or cryogenic method. Hold at the temperature for 1 hour per inch (25.4mm) of density, 2 hours particle, then air cool to ambient heat. Tempering temperatures and hardness are given in chart over.